- 首頁

- 產品服務

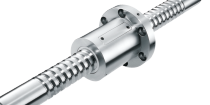

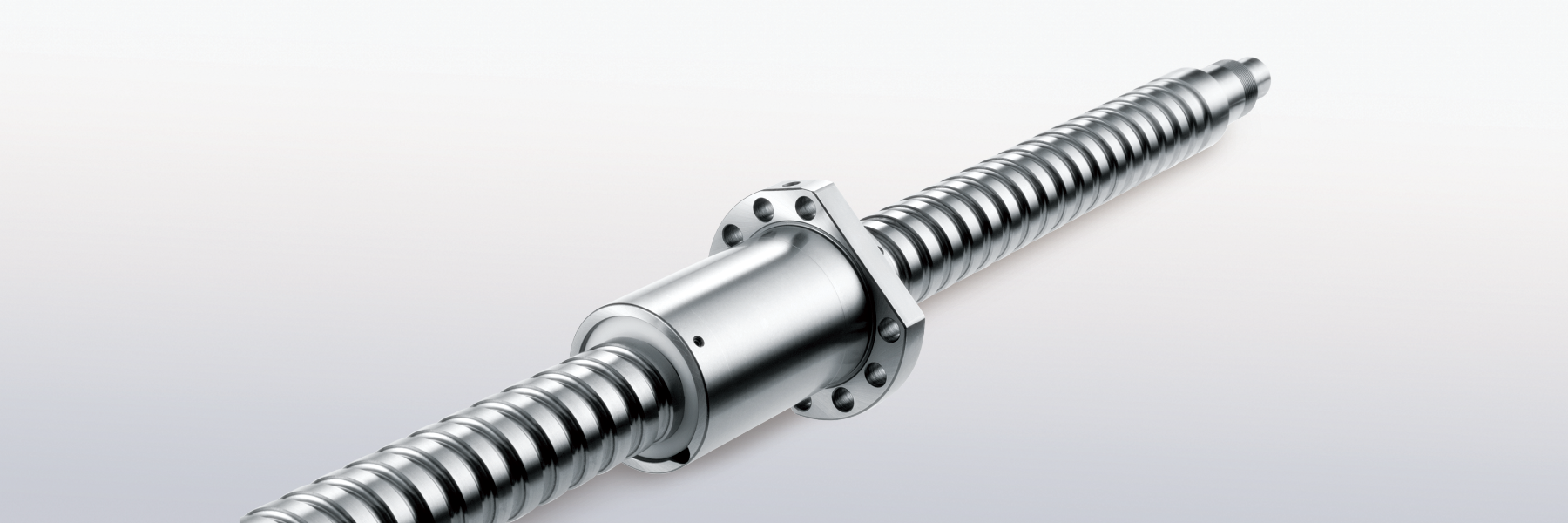

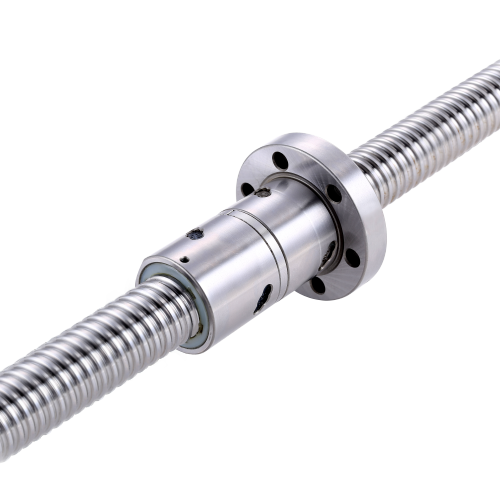

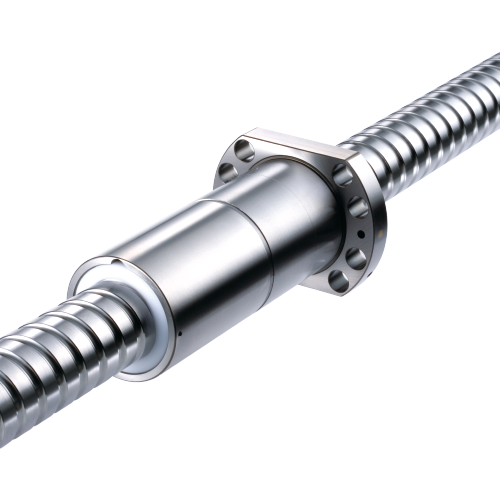

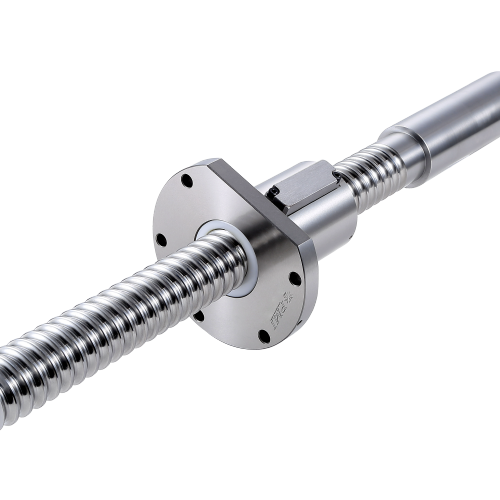

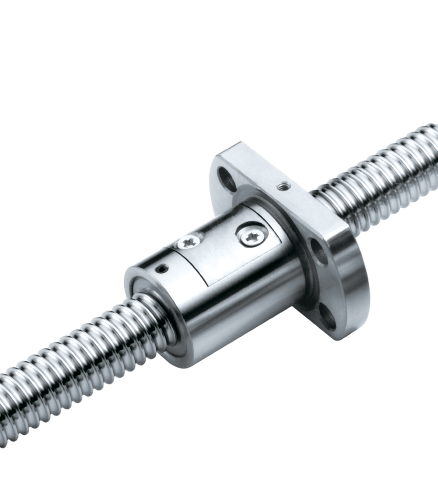

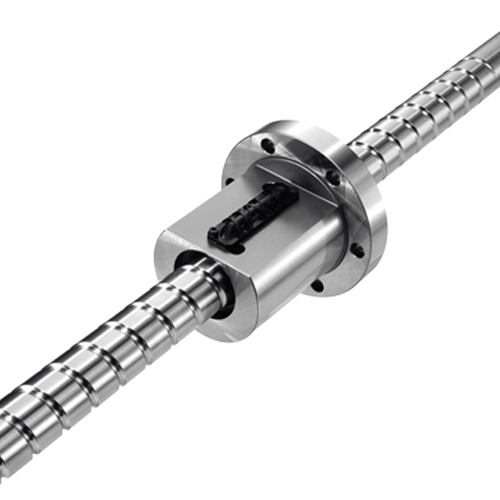

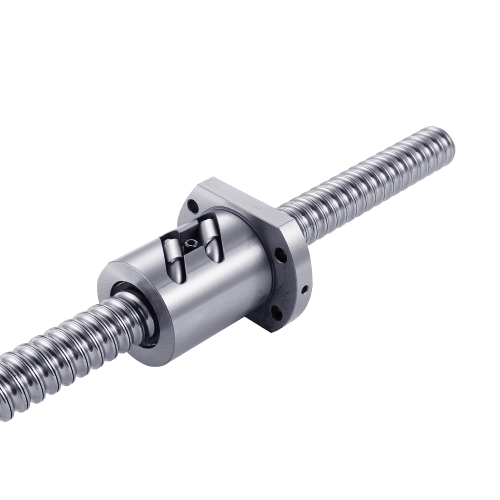

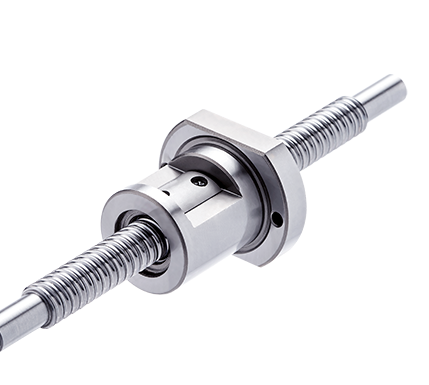

- 滾珠螺桿

產品特點

高信賴度

PMI之滾珠螺桿是三十多年來所累積製造技術為基礎,從材料、熱處理、設計、生管、品管到出貨,都有一定的處理作業,其制度化的管理讓我們的滾珠螺桿給顧客高度的信賴度。

高精度的保證

PMI之滾珠螺桿其螺桿與螺帽都在恆溫室做精密加工、研磨、裝配及品管,可保證高精度的品質。

優異的耐久性

PMI以累積三十多年的滾珠螺桿的生產技術,採用德製鋼材施以本公司特有之處理及研磨技術,可供給耐久性優異的滾珠螺桿。

高效率

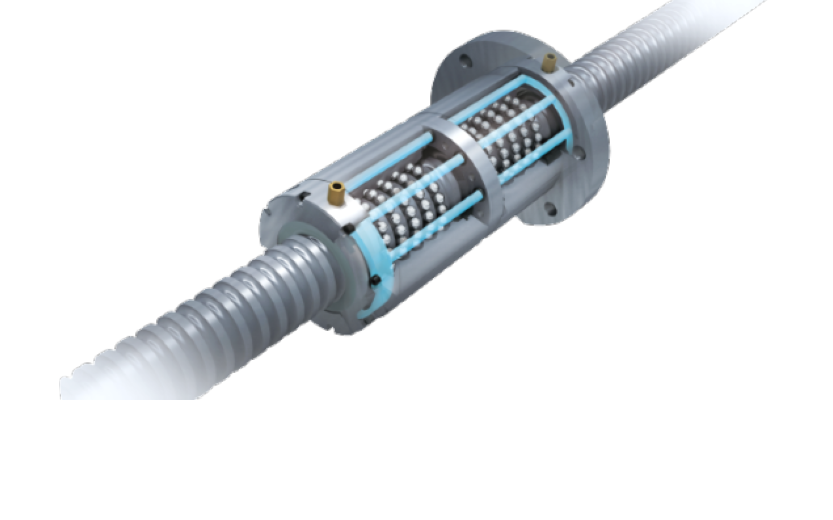

滾珠螺桿其運轉是靠螺帽內的鋼珠做滾動運動,比傳統滑動螺桿有更高的效率,所需的扭距只需有傳統滑動螺桿的1/3以下。所以可輕易地將直線運動轉變為回轉運動。

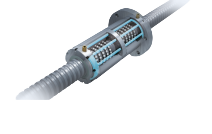

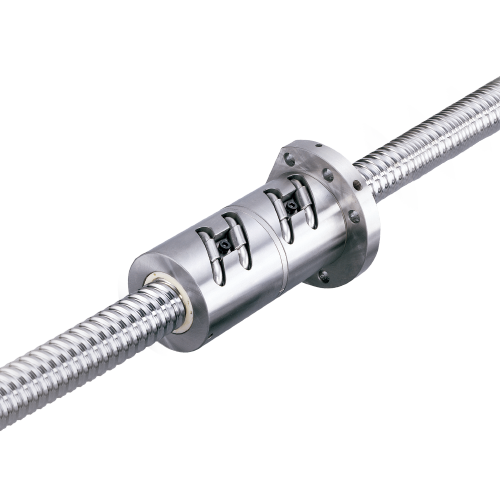

無背隙與高剛性

PMI之滾珠螺桿採用哥德式(Gothic arch)溝槽形狀,使鋼珠與溝槽能有最佳接觸以便輕易運動。若加入適當的預壓力,消除軸方向間隙,可使滾珠螺桿有更佳的剛性,減少滾珠和螺帽、螺桿間的彈性變形,達到更高的精度。

產品列表

-

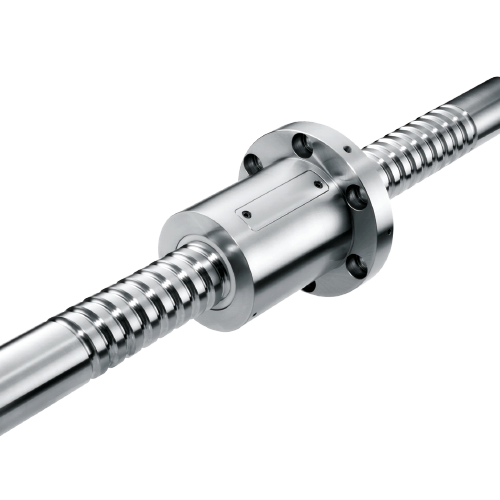

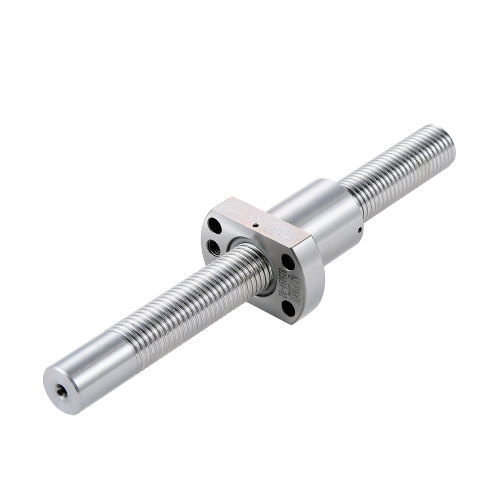

精密級滾珠螺桿

-

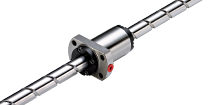

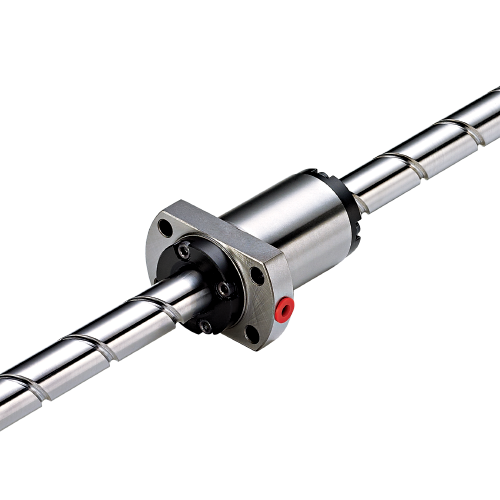

轉造級滾珠螺桿

-

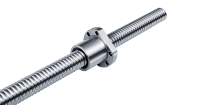

自動化產業專用型螺桿

-

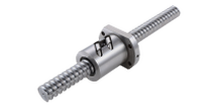

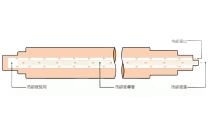

冷卻系統

-

配件