- Home

- About Us

- Corporate History

2013

- In March the capital was increased to one billion Taiwan dollars.

- We were one of the 74 selected companies as a medium-sized enterprise to receive government counseling and assistance.

2012

- Plants 1 and 2 in Feng Chou High-tech Industrial Park were officially launched.

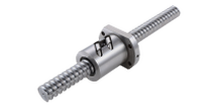

- In March we worked with the technological industry to carry out a two-year program named "Technology Development Program – Program of developing nano grade blue ray laser direct-writing equipment and its application to enhance the light extraction efficiency of LED". We applied such technology of "Long travel nano grade precision platform" as developed in 2006 to the industry.

2011

- We were awarded the silver medal on the assessment of TTQS training quality.

- Ms Mei-Xiu HONG, Manager of Management Department, was honored with the national Outstanding Manager Award and that for central Taiwan.

2010

- We were awarded the prize of "Health Workplace Benchmark Plants" by Bureau of Health Promotion, Department of Health, Executive Yuan.

- We were awarded the bronze medal on the assessment of TTQS training quality.

2009

- We were accredited with OHSAS-18001 in May.

2008

- Capital was increased to 800 million Taiwan dollars.

- We participated in the program of "Planning and Counseling on OHSAS-18001".

- In December we merged our subsidiary "鼎耀科技". After that, our capital was NT$997,726,590.

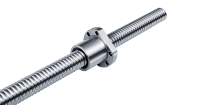

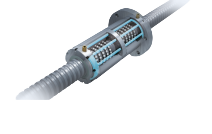

- We completed the leading new product project of "high rigid axial loading lead screw" and began to produce the product.

- After the aforementioned merger, we started to expand domestic and overseas markets under the new brand name

as modified.

as modified.

2007

- An overseas subsidiary named 銀鼎精密元件(上海)有限公司 was set up.

- The Barcode of DSI system was adopted in February.

- Accreditation of ISO9001 was successfully transferred in July.

- PMI was accredited with ISO14001 in July.

- Capital was increased to 630 million Taiwan dollars.

- We developed "High rigid axial loading lead screw", and this project of leading new product was approved by Minister of Economic Affairs.

2006

- An overseas subsidiary named 銀鼎傳動元件(上海)有限公司 was set up.

- The new factory was put into operation in July.

- ISO 14000 was under planning.

- We expanded domestic and overseas markets under our brand name

- The capital was increased to 530 million Taiwan dollars.

- We concluded the 2nd "Grand Project of Industry-University Cooperation" with National Science Council.

- We completed the 3-year "Grand Project of Industry-University Cooperation" held by National Science Council. The project was named "The research and manufacture of long travel, nano-grade and precision platform".

2005

- The paid-in capital was 330 million Taiwan dollars.

- ERP system go-live.

- RoHS green environment system was prompted.

2004

- JDE ERP was introduced into our information system.

2003

- PMI was accredited with ISO9001 2000.

- Capital was increased to 281 million Taiwan dollars.

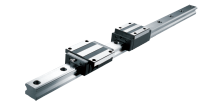

- To be an international manufacturer specialized in "Linear Transmitting Components", we recruited experienced talents to organize "Linear Guide Rails Development Committee" especially responsible for research, development, manufacture and sales of the linear guide rails.

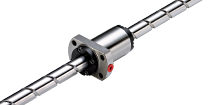

- We achieved a business objective of taking over 50% market share in domestic high precision ball screw market.

- In October we concluded a 3-year "Grand Project of Industry-University Cooperation" with National Science Council. Precision Machine Center of National Formosa University carried out the project, being fully responsible for research and development with respect to the manufacture method for nano-grade long travel precision platform, and finally transferred to us such 7 kinds of precision measuring technologies as developed which reinforced our R&D ability, upgraded our product functions and competition force for us to stride toward nano high technology industry.

became the image logo of PMI GROUP.

became the image logo of PMI GROUP.

2002

- We obtained the patent on the technology of "Lubrication structure of retainer of ball guide screw".

- Capital was increased to 227 million Taiwan dollars.

2001

- Obtained the patent right of "Ball Screw Cooling Structure Improvement".

- Capital was increased to 205 million Taiwan dollars.

2000

- PMI continuously broke the bottlenecks in research and development, and successfully acquired the patent on the technology of "Improved nut seat circulation flow guiding tube of ball screw".

- Capital was increased to 158 million Taiwan dollars.

1999

- We successfully achieved a breakthrough in manufacturing capacity and acquired the patent on "Structure of the Nut of Ballscrew".

1998

- Capital was increased to 120 million Taiwan dollars.

1997

- PMI successfully became an ISO9001 Q. A. System certified plant based on the accreditation of AMTRI VERITAS, UK.

- Capital was increased to 23 million Taiwan dollars in response to increasing orders from the customers. Several thread grinders were purchased from Japan and added to production line.

1996

- High precision thread grinder of MITSUI, Japan was introduced to the production line and the first-stage extension to the plant was fulfilled so as to enhance productivity and upgrade production technology.

- Capital was increased to 13 million Taiwan dollars.

1995

- We started to expand business with "PMI" brand in the domestic and overseas markets.

1991

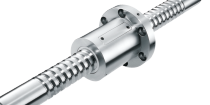

- The first ballscrew was produced.

1990

- PMI Precision Motion Industries, INC. was founded, with 7 million Taiwan dollars capital registered and 165 M2 plant building area, to be engaged in development and manufacture of general lead and precision ballscrews.